Valve Stem Seals

Valve stem seals control oil flow to engine valve stems, ensuring proper lubrication while preventing oil leakage into the combustion chamber.

Product Description

Valve stem seals are precision engine components that regulate the flow of lubricant between the valve stem and valve guide. They help minimize oil consumption, reduce emissions, and maintain engine efficiency by preventing excess oil from entering the combustion chamber.

Features & Benefits

1. Accurately controls oil flow while maintaining proper lubrication of the valve stem.

2. Constructed from high-temperature, oil-resistant materials to perform reliably under engine heat and pressure.

3. Reduces wear, prevents oil burning and deposits, and extends the service life of the valve train.

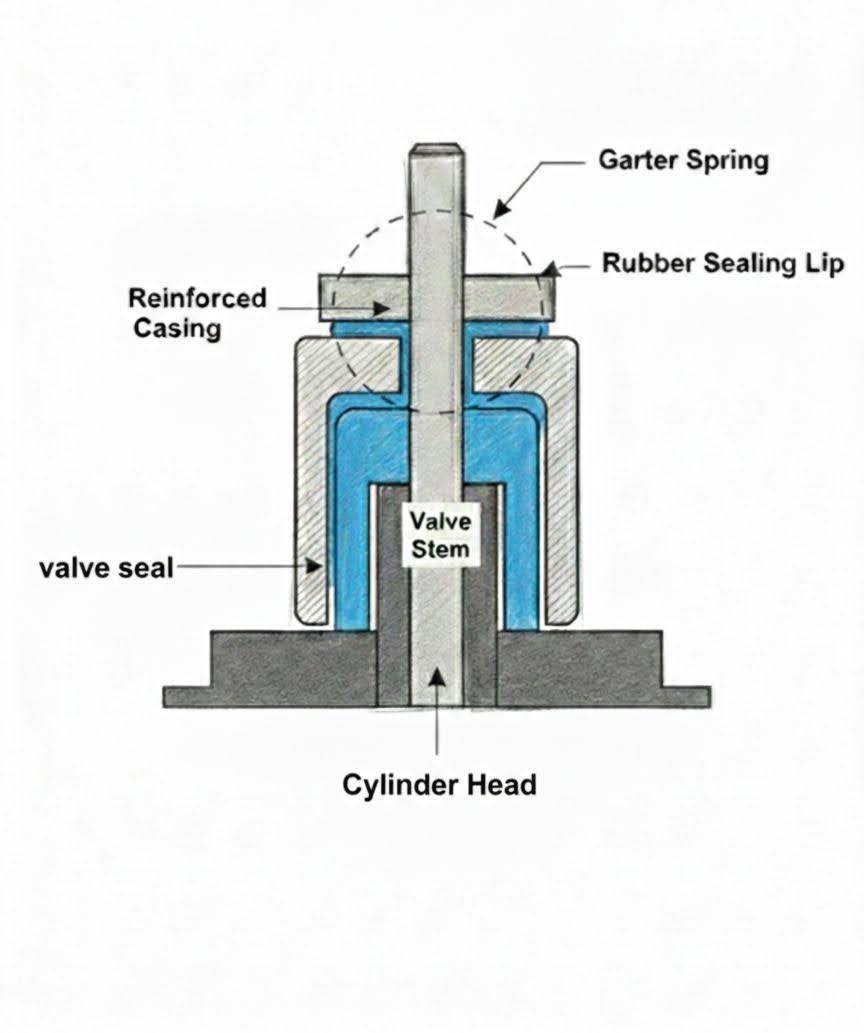

Basic Structure

A valve stem seal typically consists of a metal or reinforced casing combined with a rubber sealing lip. The sealing lip fits tightly around the valve stem, while the outer body is securely seated on the valve guide to maintain stable sealing during engine operation.

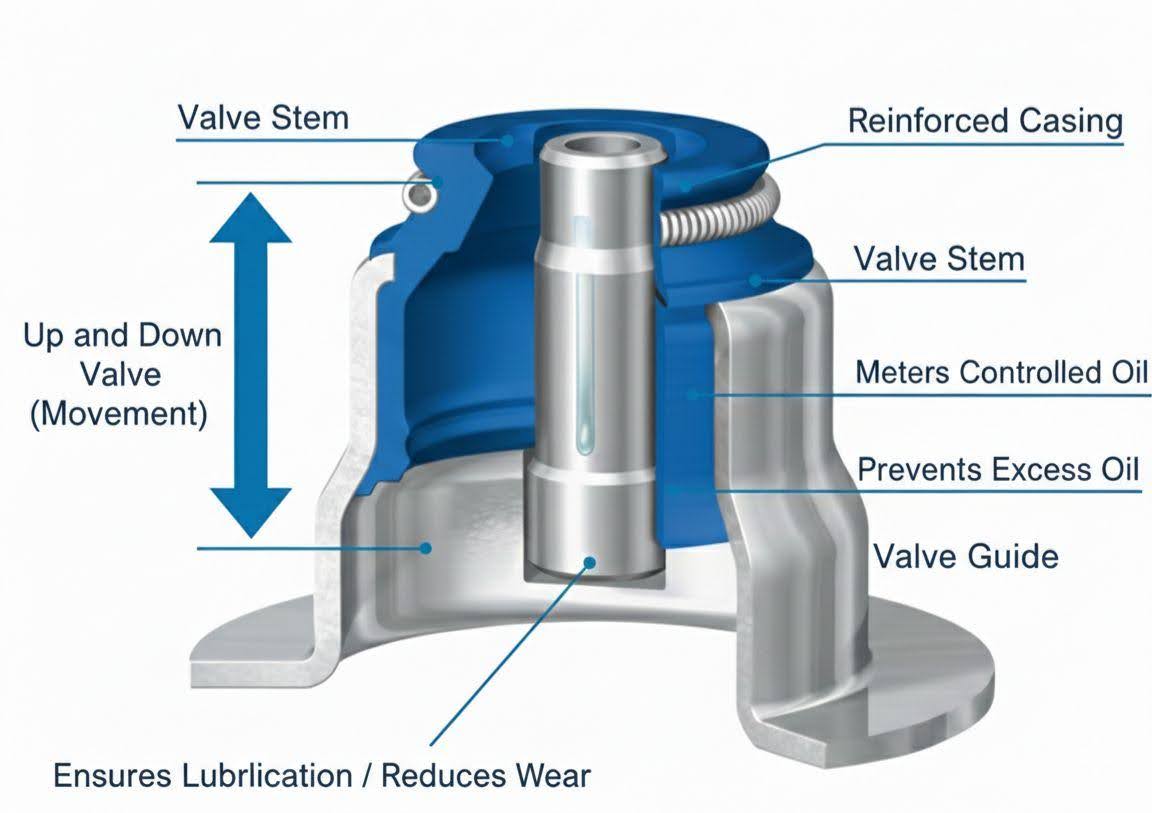

Sealing Theory

As the valve moves up and down, the valve stem seal meters a controlled amount of oil along the valve stem. The elastic sealing lip prevents excess oil from entering the combustion chamber while ensuring sufficient lubrication to reduce wear and friction.

Handling Instructions

- Store in a clean, dry environment away from sunlight, heat, and chemicals.

- Handle carefully to avoid damage to the sealing lip.

- Use proper installation tools to prevent deformation or misalignment.

- Inspect for damage before installation to ensure reliable sealing performance.

Usage Example

Automotive engines, commercial vehicles, motorcycles, agricultural machinery, and industrial engines, where precise oil control and long engine life are required.

Product Selection Program

REQUEST A QUOTATION

We would be happy to review your sealing and application requirements. Share your product specifications and operating conditions, and our technical team will provide a suitable sealing solution within 24 hours.

Our engineers ensure accurate material selection, dimensional compatibility, and performance optimization based on your industry standards.

Request a QuoteInquiry

Share your requirements and our team will contact you shortly.

Share your requirements and our team will contact you shortly.